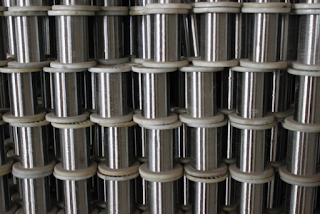

QunKun company has more than 10 years history , rich production experience, we produced the Galvanized wire .

Galvanized wire Production process: it is made of high quality low carbon steel wire rod processing and into, is made of high quality low carbon steel, after drawing molding, pickling derusting, high temperature annealing, hot dip galvanized. Cooling process.

Galvanized wire application: products are widely used in various fields such as construction, handicraft, weaving screen, highway fence, product packaging and daily civil service

.

Galvanized wire is divided into hot galvanizing wire and cold galvanized wire (electro galvanizing wire).

Hot galvanizing is the dip and plating of molten zinc in molten zinc, the production speed is fast, the coating thickness is not uniform, the minimum thickness of the market is 45 microns, the maximum can be up to 300 microns.The color is darker, consume zinc metal more, form infiltration layer with the base metal, the corrosion resistance is good, the hot galvanizing in the outdoor environment can be kept for several decades.

Cold galvanizing (electric galvanized) is in the plating bath by current unipolarity zinc plating on metal surface gradually, production speed is slow, uniform coating, the thickness of thin, usually only 3-15 microns, bright appearance, corrosion resistance is poor, usually a few months will rust.

Application scope of hot-dip galvanizing:

Because of the thickness of the coating, hot galvanizing has better protective properties than electro galvanizing, so it is an important protective coating for steel parts used in harsh working environment.Hot dip galvanized products in chemical equipment, oil processing, Marine exploration, metal structure, electricity, shipbuilding and other industries are widely used, in agriculture such as pesticides, sprinkler irrigation, greenhouse and construction such as water and gas transmission, wire casing, scaffolding, bridge, highway guardrail, etc., widely adopted now.

our company well received by the people worldwide, because of the good price and high-quality, welcome you to come to the inquiry.

Cold galvanizing (electric galvanized) is in the plating bath by current unipolarity zinc plating on metal surface gradually, production speed is slow, uniform coating, the thickness of thin, usually only 3-15 microns, bright appearance, corrosion resistance is poor, usually a few months will rust.