TECHNICAL REQUIREMENTS

2.1. Barbed wire must be manufactured in accordance with the requirements of this standard for technological regulations, approved in accordance with the established procedure.

Wire for warp and thorns of barbed wire should be made of wire rod. Manufacture of a wire from a steel of mark 08кп in accordance with GOST 1050 is admissible.

2.2. The basis of the barbed wire is made of heat-treated wire, which should have a temporary tensile strength of at least 350 N / mm2 (36 kgf / mm2) and withstand at least five 180-degree bends without breaking.

2.3. Thorns of barbed wire are made of thermally untreated wire with a temporary rupture resistance of not more than 1180 N / mm2 (120 kgf / mm2).

2.4. The ends of the studs must be straight and sharp (the angle of sharpening should correspond to that indicated on the drawing). It is allowed to blunt and bend at most one spike on every meter of the barbed wire.

2.5. Spikes should sit on the ground motionless. It is allowed to check the studs around the base at an angle of no more than 30 ° and move the studs along the base within the distance between the protrusions of the base.

2.6. It is allowed to skip the spikes, as well as the presence of spikes that do not meet the requirements of clause 2.5, in sections with a length of no more than 0.5 m, provided that the total length of such sections in the skein does not exceed 4 m and the distance between them is not less than 5 m.

2.7. On the surface of the base of uncoated wire, foils, shells, cracks, stratifications and rust are not allowed.

Longitudinal and transverse risks are allowed on the surface of the uncoated studs.

2.10. The zinc coating on the wire intended for the substrate must be continuous. Local floods of zinc are allowed.

The zinc coating on the wire intended for the studs should be solid, strong and should not crack and flake off when spiraling the wire with five turns on a cylindrical core equal to the diameter of 2.75 mm for a wire of galvanized 1 and 2 classes and equal to 4 times the diameter of the wound wire for zinc-coated wire 3 and 4 classes.

Presence of surface dust-like peeling of the zinc coating on wounded specimens is allowed.

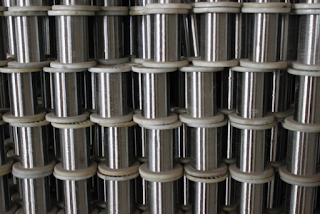

2.14. The wire should be made in coils with a mass (35 ± 2) kg with an outer diameter of a hank less than 600 mm, a height of not more than 250 mm. The inner diameter of the coil of wire should be from 100 to 140 mm. The conicity of the hole is possible in the same range.

Note. The length of the wire in a coil of 35 kg is approximately 400 m.

2.15. In a skein, no more than two barbed wire connections are allowed. The joining of the ends of the segments must be carried out in the form of loops entering one into the other. The fastening of the hinges should be done by firmly nailing at least four turns of each bent end of the loop around the base.